Ferdinand von Ubisch

- FastDocking

- +47 474 76 610

- Send e-mail

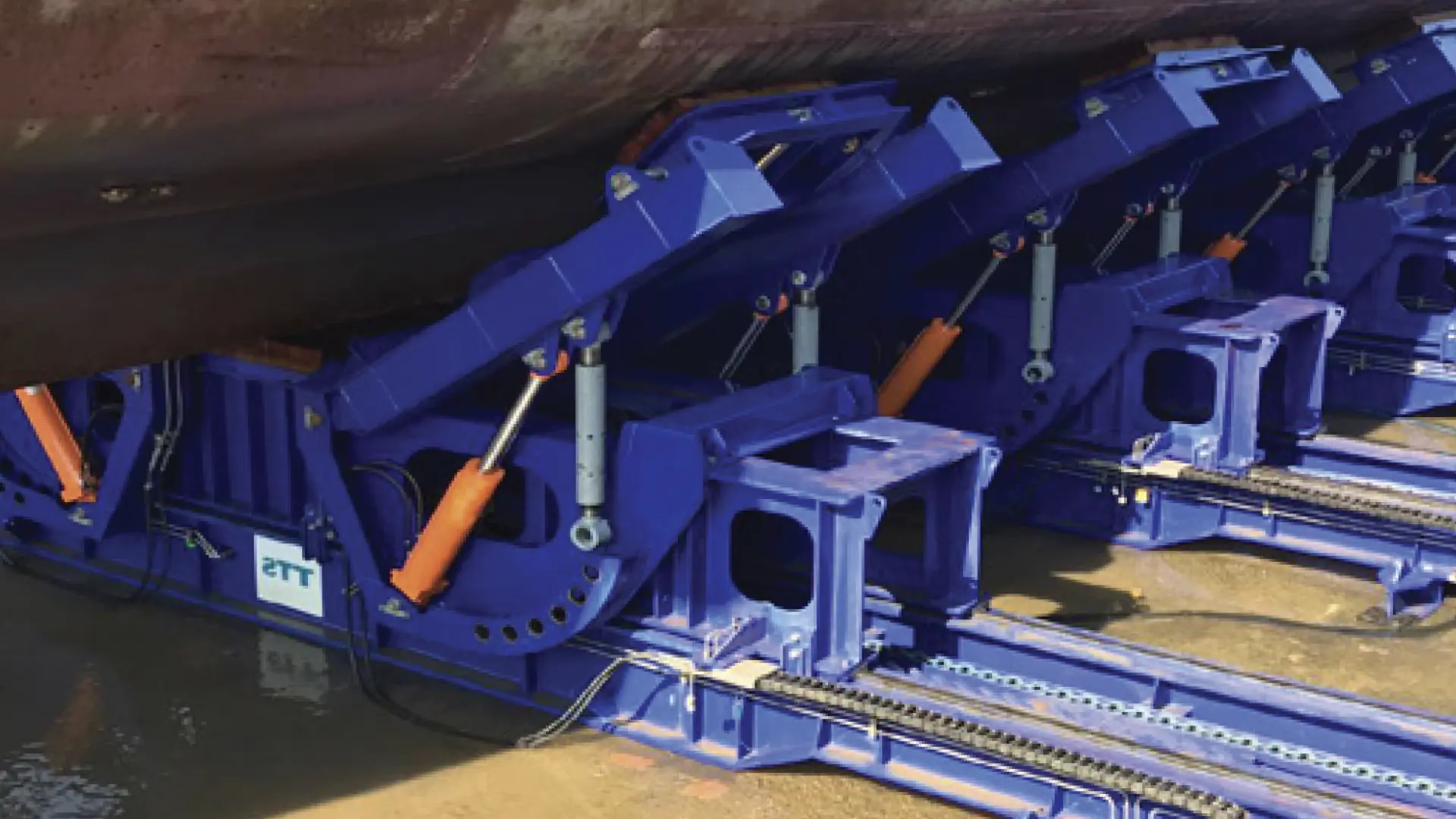

Our Flex Pads, made of high-quality polymer compounds engineered to be a reliable and long-lasting solution, substitute crushed wood used on keel blocks.

In most shipyards today, wood is still used to give a cushion effect whether transferring ships on land or blocking ships in a drydock.The logistics and cost of cutting trees, machining, handling etc. is not cost efficient nor environmentally friendly.

The softwood part of the block is changed for every docking while FlexPads can do 50-100 dockings.

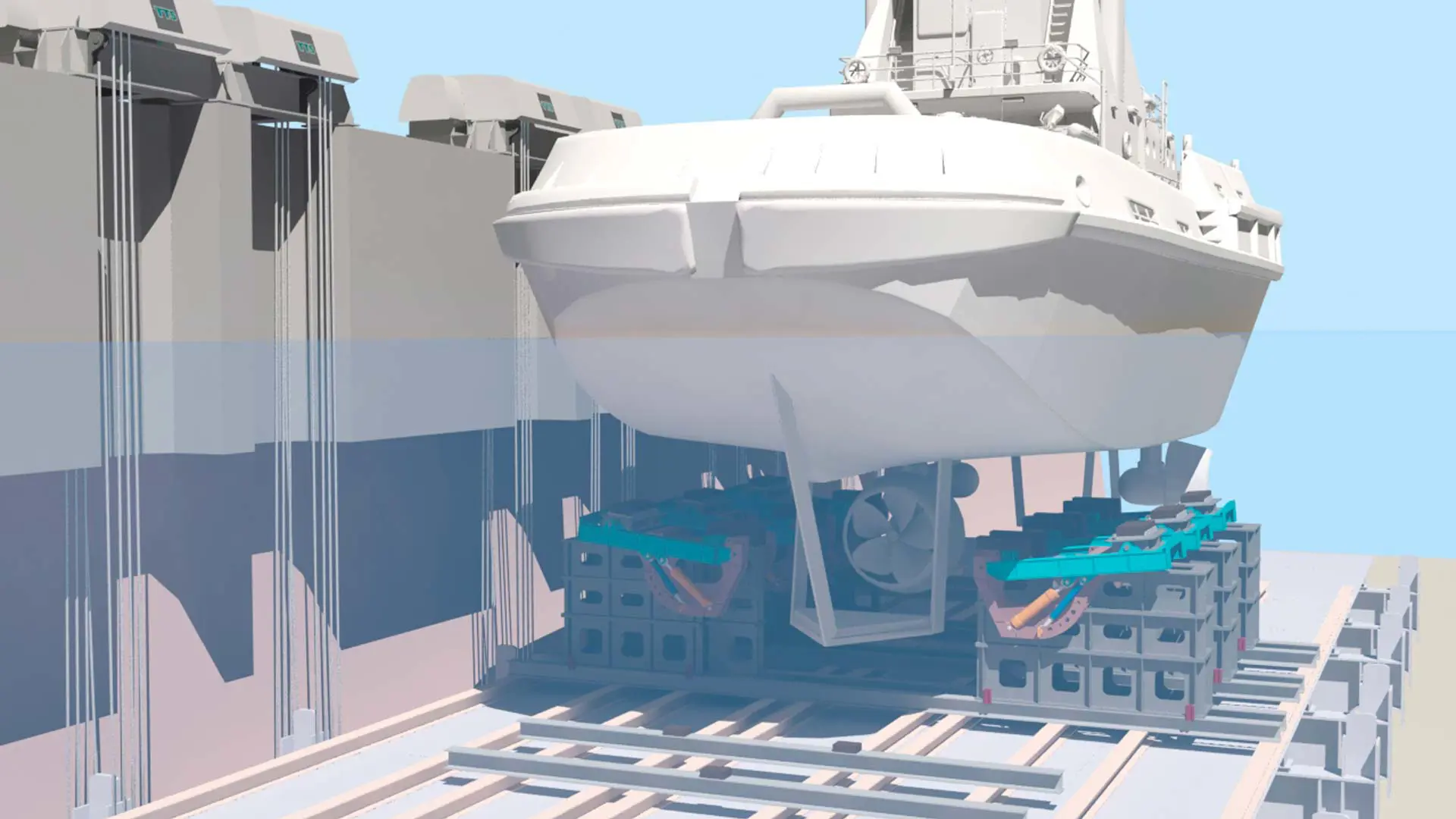

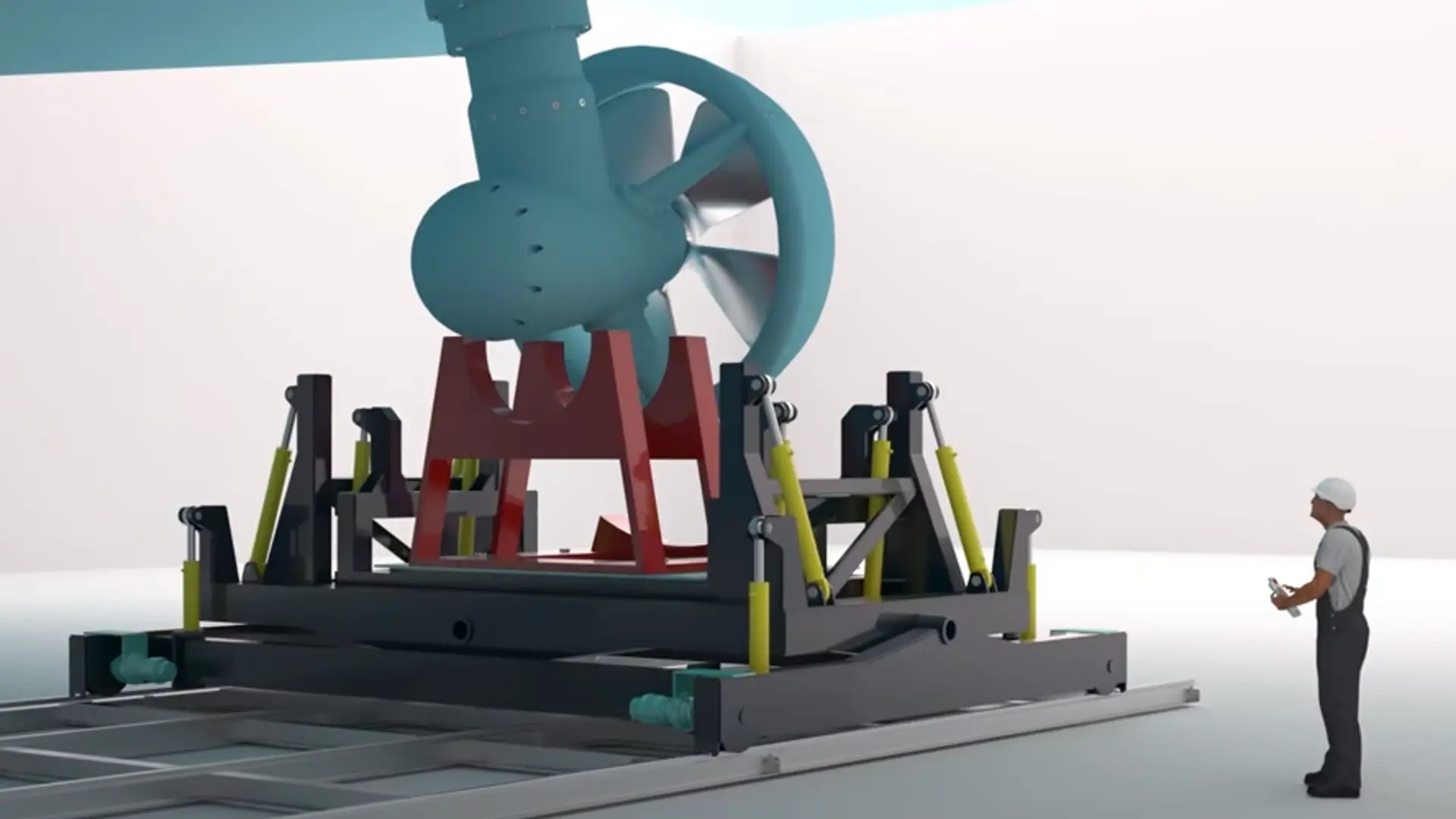

The FlexPads are not only a cost-efficient investment, but through their LEGO-like application will speed up and simplify the hull and keel block assembly.

Enhanced Load Distribution: Flex Pads are designed to deflect up to 50mm, allowing for better distribution of the load across the keel blocks. This feature helps minimize pressure points on the vessel's hull, reducing the risk of damage and enhancing the safety of the docking process.

High Load Capacity: Each Flex Pad is capable of supporting loads up to 1000 tons per square meter, making them suitable for a wide range of vessel sizes, from small boats to large commercial ships.

Durability and Longevity: Made from high-quality polymer compounds, Flex Pads are engineered to be a long-lasting solution that withstands the harsh conditions of marine environments. Unlike traditional wood blocks, Flex Pads do not degrade or splinter, ensuring consistent performance over time.

Cost Efficiency: The reusable nature of Flex Pads not only reduces the need for frequent replacements but also decreases waste produced by the shipyard. This cost-efficiency is complemented by the pads' minimal maintenance requirements.

Environmental Sustainability: Flex Pads offer an eco-friendly alternative to wooden keel blocks, reducing the shipyard's reliance on timber resources and minimizing its environmental footprint.

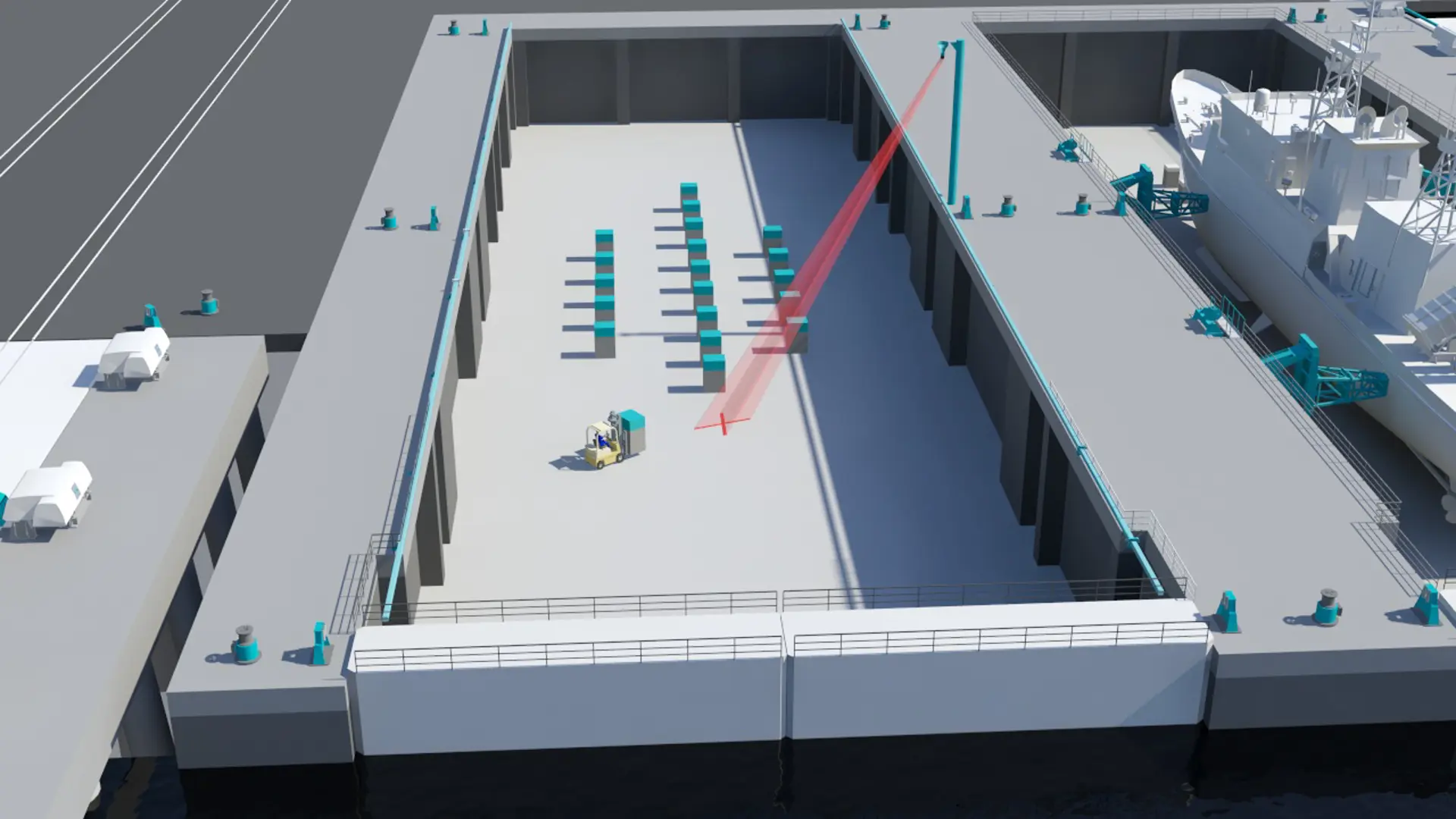

Syncrolift Flex Pads are particularly beneficial for shipyards engaged in frequent docking operations, especially those handling a diverse range of vessel types. They are also suitable for facilities looking to enhance their environmental sustainability practices and improve safety standards in docking operations.

--

Please reach out to us if you want to know more about our shiplifts, transfer systems and services!